Stevenson Company’s new MultiCam CNC router fuels additional food-safe manufacturing abilities for customers. The combination of a CNC router for plastics and a plasma cutter that can blast through stainless steel offer fast, precise solutions for customers.

The new CNC model, known as the Apex, is the same machine used in the aerospace industry and by America's largest manufacturer of motorcycles.

“These technologies make part creation fast and highly precise,” says Stevenson Company president Joe Pennington. “These parts can be easily produced with phenomenal tolerances and ultra smooth surfaces.”

“We’re always looking ahead for ways to adapt to the changes in the way America's treats are made,” says Pennington. Food manufacturers recognize the benefits of handling product using plastic: it's a sanitary surface that’s easily cleanable, with excellent ability to increase flow.

"This state of the art machine expands services to our customers, and widens our product offering. We’re very excited to offer solutions in this new way.”

After cutting, machined parts can be welded into various shapes:

- funnels

- chutes

- work surfaces

- conveyor guides

- bin liners

- more

The craftsmen at Stevenson have established a reputation as adept manufacturers of innovative equipment. Now, we’ve added the capacity with our new machine housed in a sparkling 2,000 square foot CNC shop—sized with an eye on future additions.

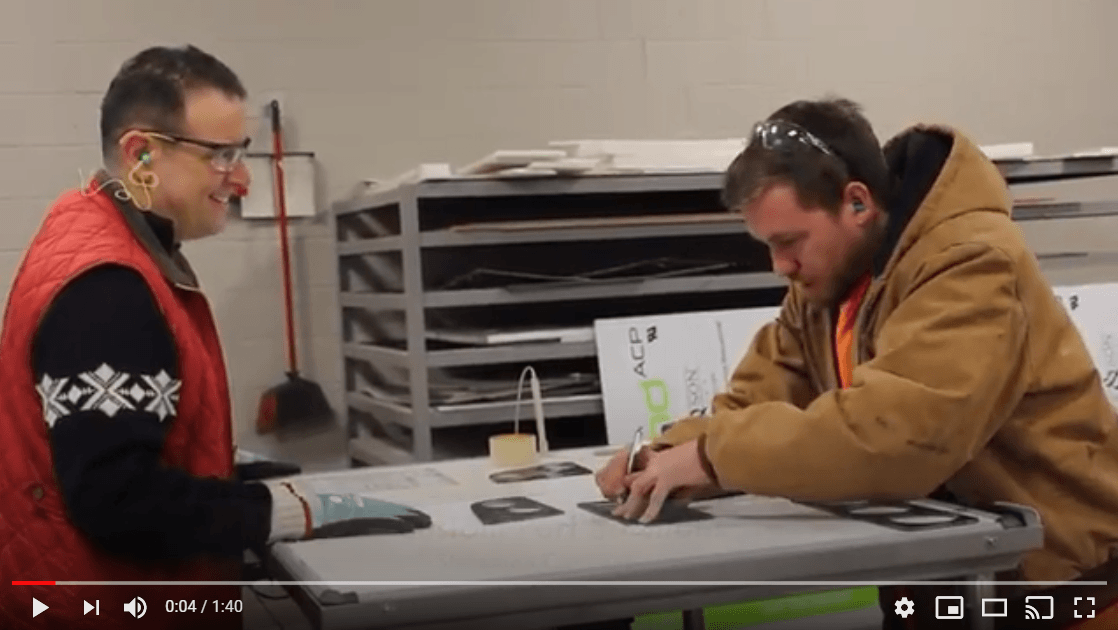

Training operators were provided by MultiCam, and the local economic growth organization, Greater Topeka Partnership, subsidized the education of an additional employee. Pennington is also scheduled to participate in immersive training at the equipment factory next month in Dallas.

Stevenson is always looking forward to producing lots of parts for the world's best customers. “This purchase was a direct response to customer demand, and we are excited to demonstrate our skills and abilities,” says Pennington.

Stevenson Company, Inc. is a sheet metal expert, with a specialty focus on stainless steel spiral chutes and other key components for manufacturers of food or fragile products. Stevenson also provides industrial plant maintenance and support for manufacturing companies. For over 60 years, we’ve built a reputations for engineering custom products to solve difficult manufacturing structural problems. Innovation, craftsmanship and quality are our hallmarks.

SEE HOW IT WORKS: